Motor specs or (motor specifications) are the electrical, mechanical, and physical data of the motor.

Every motor has its own specs which should be clear on the motor nameplate. The motor data is important because any mistake while connecting or installing the motor could be destructive and costly. Motor specs are set on the motor nameplate.

The motor nameplate is unique for each motor, It has data specific to that motor. It doesn’t only for electrical specs of the motor, but also it contains other mechanical data like a motor frame.

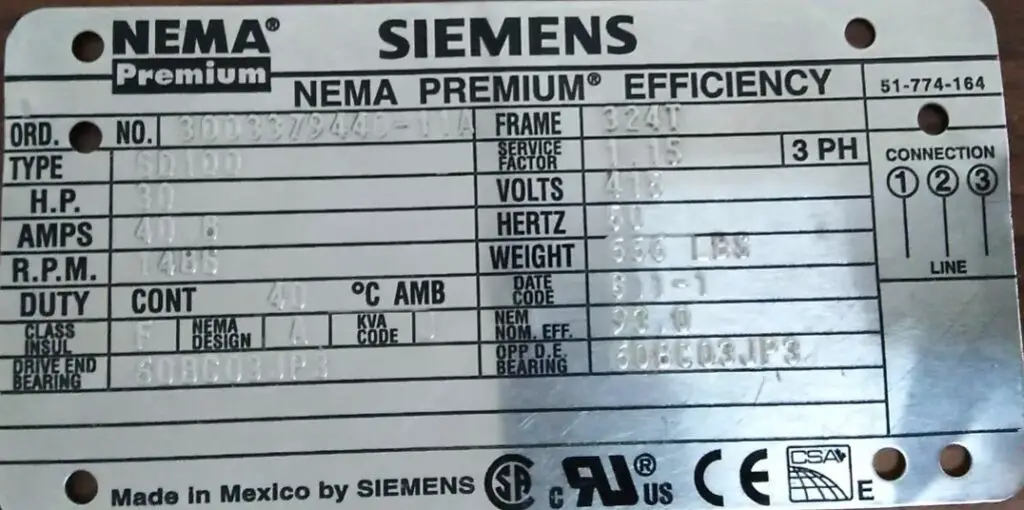

Let’s discuss motor nameplate data, with an example of a Siemens motor nameplate. Let’s get started.

Table of Contents

What does motor nameplate mean?

A motor nameplate is a metal or plastic plate that is usually found on the outside frame of an electric motor. This plate contains important information about the motor, including its specifications and electrical characteristics.

The information provided on the nameplate is essential for the proper installation, operation, and maintenance of the motor. Some of the key details typically found on a motor nameplate include:

- Motor manufacturer’s name or trademark.

- Model or type of the motor.

- Electrical specifications such as voltage, phase, frequency, and full-load current.

- Power rating, usually in terms of horsepower (HP) or kilowatts (kW).

- Speed of the motor, generally given in revolutions per minute (RPM).

- Operating temperature range.

- Insulation class and type.

- Efficiency rating.

- Duty cycle (e.g., continuous, intermittent, short time).

- Connection configurations (e.g., star, delta).

Motor nameplates are crucial for ensuring that the motor is used within its intended operating parameters, preventing potential damage, and ensuring optimal performance.

When selecting, installing, or repairing a motor, it is essential to refer to the information provided on the motor nameplate to ensure compatibility with the application requirements and to guarantee safe and efficient operation.

What is required on a motor nameplate?

A typical motor nameplate contains several important pieces of information that are crucial for understanding and operating the motor. Here are the key details you might find on a motor nameplate:

- Manufacturer’s Name: This indicates the company that produced the motor.

- Model Number or Type: It specifies the particular model or type of the motor for identification and reference purposes.

- Rated Voltage: The voltage at which the motor is designed to operate. This is essential for ensuring that the motor is connected to the appropriate power supply.

- Full Load Current (FLA): The current the motor draws when operating at its maximum rated capacity. This is crucial for sizing the motor circuit and protection devices.

- Frequency (Hertz): The frequency at which the motor is designed to operate. This is typically 50 Hz or 60 Hz, depending on the region.

- Power Rating: It is usually specified in horsepower (HP) or kilowatts (kW) and indicates the power output of the motor at the rated load.

- Speed: This specifies the motor’s operating speed, usually given in revolutions per minute (RPM).

- Efficiency: This indicates the efficiency of the motor, representing the ratio of output power to input power, often given as a percentage.

- Power Factor: The power factor of the motor indicates the ratio of real power to apparent power and is crucial for assessing the efficiency of power usage.

- Insulation Class: This specifies the class of insulation used in the motor, which determines the maximum temperature at which the motor can operate safely.

- Ambient Temperature: The range of temperatures in which the motor is designed to operate safely.

- Service Factor: The service factor indicates the level of overload the motor can handle for short periods without being damaged.

- Connection Configuration: This specifies the configuration of the motor’s electrical connections, such as whether it is wired in star (Y) or delta (Δ) configuration.

These details are critical for ensuring the safe and efficient operation of the motor and for selecting the appropriate motor for specific applications.

Electrical motor specs and nameplate understanding

Like any electrical device, electrical motors work on rated voltage and current, but there is some more data that should be taken into account.

Operating voltage

Operating voltage type AC or DC. Voltage value is important for safe operation of the motor, because, if a motor runs on low voltage, under voltage, its current increases and could be burnt.

While over-voltage causes motor winding insulation failure and then motor burnt.

Connection type

The connection type is either Delta or Star and the connection diagram of the motor is in both cases.

Rated current

Rated current of the motor. This current is important for overcurrent protection design, and also for cable and control circuit devices, such as circuit breakers and contactors. All these parts should be designed based on motor-rated current.

The current in Amperes on the motor nameplate is the full load current of the motor.

Frequency

Frequency in hertz. The power source frequency should be suitable for the motor. The motor output power on the nameplate depends on the frequency and rated voltage of the motor.

Efficiency

Motor efficiency is the percentage of output power to the input power of the motor.

Motor power

The power of the motor in KW or HP, should be suitable for the mechanical load. You can convert kw to hp if required.

You can use the HP to KW and KW to HP converter online.

Insulation class

Insulation temperature (insulation class). The MAX temperature rises so that the winding of the motor can handle normal operation. Below is the Insulation class table.

| Class A | 105 Degrees C |

| Class B | 130 Degrees C |

| Class F | 155 Degrees C |

| Class H | 180 Degrees C |

Read also my detailed article : Motor insulation class.

IP rating

IP code (ingress protection), this code determines the protection degree against dust, solid objects, and water penetrating the motor body. It consists of two numbers IP XY.

- The first number X is for dust and solid particles penetrating protection degree. It can be from 0 no protection to 6 fully protected.

- While the second letter Y is for water protection. It can be any number between 0 (No protection) and 8 (Protected against immersion in water for long periods)

Example:

IP 67 This motor is fully protected against dust ingress and also can be immersed in water for short periods.

You can find out my other article with more data about What is IP Rating? here.

Ambient temperature

Motor Ambient temperature is the maximum allowable temperature of the surroundings that a motor can work properly in.

Motors should run properly in a temperature range. This parameter is set on the nameplate as a temperature degree (i.e. 40°C AMB). If the motor ambient temperature is not mentioned on the nameplate, then it’s considered as 40°C,

Motor power factor

It shows how effectively your motor uses electrical energy. For more details about the power factor, you can find it in my other article What is Power Factor (pf)?

What to do if the power factor is not on the nameplate? In some cases, the power factor is not mentioned on the nameplate. Don’t worry in this case:

- For single phase motor, we suppose the power factor is 0.75

- For three-phase motors, we suppose it is 0.85

Motor service factor (SF)

The service factor (SF) of an electric motor is a multiplier that indicates the motor’s ability to handle temporary conditions that exceed the full-load torque or horsepower.

It provides a margin of safety for applications where the motor might experience occasional overloading or when the motor is subjected to varying or fluctuating loads.

The service factor is typically represented as a decimal or a whole number, such as 1.15 or 1.25, and is often displayed on the motor nameplate. When the service factor is multiplied by the motor’s rated horsepower or torque, it provides the maximum horsepower or torque that the motor can deliver for short periods without being damaged.

For example, if a motor has a horsepower rating of 5 HP and a service factor of 1.15, it means the motor can deliver up to 1.15 times its rated horsepower, which would be 5.75 HP, for short durations without being overloaded.

It is important to note that running a motor continuously at its service factor rating can reduce its lifespan and lead to premature failure.

Therefore, it is advisable to operate the motor as close to its rated capacity as possible and reserve the service factor for occasional or intermittent overloads. Understanding and adhering to the motor’s service factor is crucial for ensuring the motor’s longevity and efficient operation.

Is a higher service factor better?

A higher service factor can provide a margin of safety and flexibility for handling occasional overloads or variations in load conditions.

It allows the motor to temporarily deliver more than its rated horsepower or torque without being damaged. However, operating a motor continuously at its service factor rating can lead to increased heat generation, reduced efficiency, and a shortened lifespan.

While a higher service factor can offer a level of robustness and adaptability to fluctuating load conditions, it is not necessarily “better” in all cases. It’s important to use the service factor judiciously and only in situations where occasional overloading is expected.

In applications where continuous heavy overloading or operation at the service factor is required, it might be more appropriate to use a motor with a higher horsepower rating to avoid premature wear and potential damage to the motor.

Therefore, it is essential to consider the specific requirements of the application and to adhere to the motor’s recommended operating guidelines to ensure long-term reliability and efficiency.

Motor Duty cycle

The duty cycle refers to the operating time of a device compared to the total time in a given time period.

It is often expressed as a percentage and is used to describe the load or stress placed on a machine or equipment over a specific period, typically within an hour. In the context of electric motors, the duty cycle helps to determine the motor’s ability to handle varying loads and operating conditions.

There are different types of duty cycles, including:

- Continuous Duty: In this type of duty cycle, the motor runs continuously under a constant load within its specified power rating and operating conditions.

- Intermittent Duty: This duty cycle involves the motor operating for alternate time intervals with both loaded and unloaded periods. The duration of the loaded and unloaded periods can vary based on the specific application.

- Short-Time Duty: Short-time duty refers to a duty cycle where the motor is designed to operate for a short period at a constant load. The duration of the operation is predetermined, and the motor is not intended for continuous operation under such conditions.

Understanding the duty cycle of a motor is essential for selecting the appropriate motor for a specific application.

Operating a motor beyond its designed duty cycle can lead to overheating, premature wear, and potential damage.

Therefore, it is crucial to match the duty cycle of the motor with the operational requirements of the application to ensure reliable and efficient performance.

Motor NEMA design

The National Electrical Manufacturers Association (NEMA) design standards provide guidelines for the manufacturing and performance of various electrical equipment, including AC motors. These standards help ensure consistency and interoperability between different manufacturers’ products and facilitate the proper selection and application of motors for specific industrial or commercial purposes.

NEMA has established design standards for various types of AC motors, including induction motors and synchronous motors, among others. These standards cover a range of motor characteristics, such as dimensions, output power, speed, torque, efficiency, and service factors. Different NEMA designations are assigned to motors based on their specific design and operational features.

NEMA designations for AC motors typically include:

- NEMA Design A: This design is typically associated with general-purpose and moderate starting torque applications.

- NEMA Design B: These motors are designed for high-starting torque applications and are commonly used in compressors, conveyors, and other industrial equipment.

- NEMA Design C and D: These designs are intended for applications requiring very high starting torque, such as heavy-duty industrial machinery and equipment.

NEMA designations are crucial for helping engineers, manufacturers, and users understand the capabilities and limitations of AC motors.

By following NEMA standards, stakeholders can select the most suitable motor for a particular application, ensuring optimal performance and longevity.

Mechanical and physical motor data

Electric motor nameplate not only for electrical data but, also for some mechanical and physical specs.

Rotational speed (RPM).

Motor RPM is necessary for the load side. For example, a pump’s performance depends on its speed.

Motor RPM is mechanical information, in my work, I need this information when I order a new induction motor for a mechanical load. I asked the mechanical engineers about the load RPM to make sure that the motor was suitable for the load.

The most common speeds of the induction motors are 1500 and 3000 RPM, however, you will never find these numbers on the nameplate because, these are the synchronous speed, while the motor runs below it. It’s common to find the motor speed at 1485 RPM or 2890 RPM

Motor frame

The frame is represented on the nameplate in the form of letters and numbers. The physical dimensions of the motor body are set as frame size. The motor frame provides the below data:

- Shaft diameter and length.

- Bolt hole mounting dimensions.

- Mounting type (flange or foot-mounted motor).

- distance of the shaft from the ground.

Painting type

Some applications need the motor to be painted with special specs because of the environment harsh conditions.

Such as motors working on ships and in deserts or even in any highly polluted humidity environment.

When purchasing a new motor you should declare the painting type or the environmental conditions to get the right motor for your application.

Greasing tube

If you will make scheduled greasing for the motor then you should make sure it has greasing holes and its bearing is accepting grease.

Lifting holes

For heavy large motors, it is necessary to have the lifting holes to be easy to install and transport.

Cooling method

Cooling of the motor is one of the important motor specs that should be declared on the nameplate or in the purchasing specs. TEFC or ODP motors are common in various applications but the most common is TEFC (totally enclosed fan-cooled)

See Also my detailed article ODP vs TEFC Motors.

How to Write Motor data (example)

Below is the data of the three-phase induction motor, as we write it in a purchase order.

Three-phase induction motor, TEFC, 60 HP, 400V, 50HZ, Delta connected, 0.95 power factor, 1.15 SF, Ins. class F, 1500RPM, 135TS frame, IP 55, S1, ambient temperature 40ºC.

Important notes for the buyer:

- No greasing tube is required.

- A lifting hole should be included.

- Painting of the motor should be able to stand out in harsh environments, and high humidity.

- Bolts should be corrosion-resistant.

Note that, not all specs are on the motor nameplate. But I mentioned it as required.

Which power is mentioned on the nameplate of a motor?

The power mentioned on the nameplate of an electric motor typically refers to its rated power. This is the maximum power output that the motor can deliver under the specified operating conditions without exceeding its temperature limits or other safety parameters.

The power rating is usually indicated in terms of either horsepower (HP) or kilowatts (kW), depending on the standard used in the particular region or country.

Understanding the power rating is essential for selecting the right motor for a specific application, as it indicates the motor’s capacity to perform the required work. Operating a motor above its rated power for extended periods can lead to overheating, reduced efficiency, and potential damage to the motor.

It’s important to note that the power mentioned on the nameplate does not necessarily reflect the actual power consumption of the motor during operation. The actual power consumption can vary depending on the load, efficiency, and other factors affecting the motor’s performance.

Why motor nameplate current is not the same as the motor’s actual current?

The current indicated on a motor’s nameplate is typically the full load current (FLC) or full load amps (FLA) that the motor is expected to draw when operating at its rated load under normal operating conditions.

This value is provided as a reference to help in sizing the electrical circuits, protection devices, and other components connected to the motor.

However, the actual current drawn by the motor during operation can vary for several reasons:

- Load Variations: The current drawn by the motor can change depending on the load requirements. If the motor is operating under a load that is different from the rated load, the actual current may deviate from the nameplate value.

- Operating Conditions: Factors such as temperature, altitude, and ambient conditions can affect the motor’s performance and current draw. Higher temperatures, for instance, can lead to increased resistance and higher current draw.

- Efficiency: The efficiency of the motor influences the actual current drawn. Lower-efficiency motors might draw more current to produce the same output compared to higher-efficiency models.

- Power Factor: The power factor of the motor can also influence the current drawn from the power supply. A lower power factor can lead to an increase in apparent power and consequently the current drawn from the supply.

It is important to consider these factors when assessing the actual current drawn by a motor during operation.

Regular monitoring and maintenance can help ensure that the motor operates within its designed parameters and that any deviations from the expected current draw are identified and addressed.

Does the motor nameplate have a starting current rating?

On the motor nameplate, the starting current value is not stated, but the motor KVA code makes it simple to determine a motor’s starting current from its letter code.

The code letter value, the horsepower, the rated voltage, and the operational power factor of the motor are all mathematically related.

It is crucial to remember that changing a lower code letter to a higher code letter may involve changing other electrical equipment upstream, such as the motor starter. Calculation and example of motor starting current (LRA) by using NEMA KVA on the motor nameplate.

For the calculation, we should know each value of the NEMA KVA code, so let’s go through these values to review the table given below.

| NEMA Letter Code | Locked Rotor, kVA/HP |

| A | 0- 3.14 |

| B | 3.15 – 3.55 |

| C | 3.55 – 3.99 |

| D | 4.0 – 4.49 |

| E | 4.5 – 4.99 |

| F | 5.0 – 5.59 |

| G | 5.6 – 6.29 |

| H | 6.3 – 7.09 |

| J | 7.1 – 7.99 |

| K | 8.0 – 8.99 |

| L | 9.0 – 9.99 |

| M | 10.0 – 11.19 |

| N | 11.2 – 12.49 |

| P | 12.5 – 13.99 |

| R | 14.0 – 15.99 |

| S | 16.0 – 17.99 |

| T | 18.0 – 19.99 |

| U | 20.0 – 22.39 |

| V | 22.4 – and up |

Example:

Consider a motor that has a 50 HP motor rating and a 50 A-rated current. using the G code. The motor’s locked rotor current will now be calculated. You can see from the table that the locked rotor range for Code letter G is 5.6–6.29 KVA/HP.

Formula: Motor Starting Current (LRA) = KVA/HP × HP ×1000 =1.732 ×V × I

The lower range of locked rotor current will be as follows:

LRA = 5.6×50×1000 = 1.732 ×440 × I

LRA =280,000= 762 × I

LRA = I = 280,000 ÷ 762

LRA= I = 367 Amperes

Now upper range of the locked rotor current will be as follows:

LRA = 6.29×50×1000 = 1.732 ×440 × I

LRA= I = 412 Amperes

Thus, the starting current range for 50 HP motors is 367A to 412A.

What does sFA mean on the motor nameplate?

On a motor nameplate, “sFA” typically refers to the “Service Factor Amps.” The Service Factor Amps (SFA) represent the amount of current the motor can draw when operating at the service factor load.

The service factor is a multiplier that represents the motor’s ability to handle occasional overloads or variations in the load. When the motor operates at the service factor load, the current drawn may be higher than the full load current (FLA) specified on the nameplate.

Understanding the sFA is crucial for ensuring that the motor is not subjected to continuous overloading, which can lead to overheating and premature failure. It’s important to operate the motor within its recommended service factor limits to ensure optimal performance and longevity.

If you encounter “sFA” on a motor nameplate and need more specific information or clarification, it’s advisable to consult the motor’s documentation or reach out to the manufacturer for further guidance. They can provide detailed information about the motor’s service factor and the associated operational parameters.