Introduction

Electric motors are an essential component of most industrial applications, and the efficiency of the motor depends on its ability to operate without interruptions. However, dust and debris are inevitable in most industrial environments, and they can significantly affect the motor’s performance and lifespan. In this article, we will discuss the effects of dust and debris on ODP motors and how to mitigate the risks.

Table of Contents

What is an ODP motor?

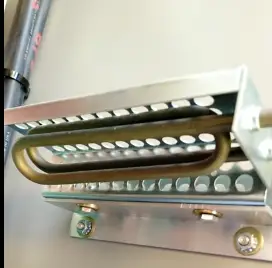

ODP stands for Open Drip Proof, which is a type of motor enclosure. An ODP motor is designed with ventilation openings in the enclosure to allow air to circulate freely around the motor.

This type of motor enclosure is suitable for indoor environments where there is no risk of water spray or exposure to corrosive substances. However, an ODP motor is not completely sealed, and it is susceptible to dust and debris.

How does dust affect ODP motor performance?

Dust and debris can accumulate on the motor’s surfaces, which can clog the ventilation openings and reduce the airflow around the motor.

This can cause the motor to overheat, which can lead to premature failure. Overheating can also reduce the motor’s efficiency and increase energy consumption.

Dust can also enter the motor’s internal components, such as the bearings, and cause abrasion and wear.

This can lead to increased friction, which can cause the motor to vibrate and produce noise. Excessive vibration can also damage other components of the motor, such as the rotor and stator.

How does debris affect ODP motor performance?

Debris, such as metal shavings, can also cause damage to the motor’s internal components. If debris enters the motor’s bearings, it can cause damage to the bearing race and balls.

This can cause the motor to vibrate, produce noise, and reduce efficiency.

Debris can also cause damage to the motor’s windings, which can lead to insulation breakdown and short circuits. This can cause the motor to fail or even pose a safety hazard.

How to mitigate the effects of dust and debris on ODP motors?

Regular maintenance

Regular maintenance is essential to ensure that the motor is operating at peak performance. The motor should be inspected regularly for signs of dust and debris accumulation.

The ventilation openings should be cleaned to ensure that there is adequate airflow around the motor.

Proper storage

Motors that are not in use should be stored in a clean and dry environment. This can reduce the risk of dust and debris accumulation and prolong the motor’s lifespan.

Filtration

Installing a filtration system can help reduce the amount of dust and debris that enters the motor enclosure.

A high-efficiency particulate air (HEPA) filter can capture particles as small as 0.3 microns.

Sealed enclosure

If the motor is operating in a particularly dusty environment, a sealed enclosure may be a better option than an ODP enclosure.

A sealed enclosure can provide better protection against dust and debris.

Conclusion

Dust and debris are inevitable in most industrial environments, and they can significantly affect the performance and lifespan of ODP motors.

Regular maintenance, proper storage, filtration, and sealed enclosures are effective ways to mitigate the risks of dust and debris accumulation.

By taking these precautions, you can ensure that your motor is operating at peak performance and avoid costly repairs and downtime.