Each cable has a current carrying capacity (or cable ampacity). The value of this current is given in cable ampacity tables and depends on some factors which are called derating or correction factors.

Table of Contents

What is the Derating factor in cable sizing?

The derating factor of a cable is a number used to adjust its current-carrying capacity based on conditions like ambient temperature, installation method, burial depth, and proximity to other cables. It ensures the cable operates safely and efficiently under real-world conditions.

It is essentially a safety margin applied to the ampacity of the cable to ensure that it operates within its temperature limits.

The specific derating factors can vary depending on the type of cable, the installation environment, and the standards or regulations being followed.

These factors are usually provided by cable manufacturers or specified in industry standards such as the National Electrical Code (NEC) in the United States or the International Electrotechnical Commission (IEC) standards.

For example, when considering the ambient temperature, if the cable is expected to operate in a higher temperature environment than the standard rating, a derating factor is applied to reduce the current-carrying capacity of the cable.

The derating factor accounts for the decrease in the cable’s ability to dissipate heat, preventing it from reaching temperatures that could cause damage or create a safety hazard.

It is crucial to consult the specific standards and guidelines relevant to the installation to determine the appropriate derating factors and ensure that the cables are sized correctly to handle the expected operating conditions safely and efficiently.

Why is cable derating necessary?

Cable derating is necessary to ensure that electrical cables operate within their specified temperature limits, thereby promoting safety and preventing potential damage or hazards. Several factors can lead to the need for cable derating:

-

Ambient temperature: High ambient temperatures can decrease a cable’s ability to dissipate heat. When a cable operates in such conditions, the current-carrying capacity must be reduced to prevent the cable from exceeding its temperature limits.

-

Grouping of cables: When multiple cables are placed close together, they can affect each other’s ability to dissipate heat. This proximity can lead to an increase in temperature, necessitating a derating factor to ensure that the combined heat does not surpass the temperature limits of the cables.

-

Depth of installation: Cables installed at greater depths might experience higher temperatures due to the surrounding environment. In such cases, derating is necessary to prevent overheating.

-

Type of installation: The method of cable installation, such as direct burial, conduit, or cable trays, can influence heat dissipation. Depending on the installation type, derating may be required to maintain safe operating temperatures.

By applying the appropriate derating factors, engineers can adjust the current-carrying capacity of the cable to align with the specific environmental and installation conditions.

This precautionary measure ensures that the cable does not overheat, minimizing the risk of electrical failures, fire hazards, or damage to the insulation and other components. It is a crucial practice to guarantee the safe and reliable operation of electrical systems.

For more information about cable ampacity, you can find it in my other article here.

When should you do derating for cables?

When current flows through a wire, it generates heat. The quantity of heat produced increases as current levels climb.

The National Electrical Code (NEC) mandates conductor derating in two situations: when the ambient temperature reaches 30 degrees Celsius and when more than three cables are bundled in a conduit.

When circuits are close together, electromagnetic and physical effects can increase the temperature of the wires, making them heat up.

Placing cables close to each other or using them in areas with fluctuating temperatures can reduce their efficiency and ability to handle heat safely.

To determine how much electricity a cable can handle, it’s essential to consider the surrounding temperature. If the actual temperature differs from the cable’s design conditions, adjustments must be made to ensure the cable remains safe and functional.

By considering these factors, we can properly adjust a cable’s capacity to prevent overheating, protect its insulation, and ensure it lasts a long time.

What will happen if I don’t derate my cable?

If a cable’s capacity isn’t adjusted properly, it can overheat when carrying too much electricity. The more current it handles beyond its limit, the hotter it becomes.

Adjusting the cable’s capacity ensures it can safely carry electricity without overheating. This protects the cable’s insulation from heat damage and extends its lifespan.

Overheating occurs because electricity flowing through a cable creates resistance, which generates heat. When multiple cables are grouped together, they can increase each other’s heat levels, making proper adjustment even more important to prevent damage and maintain safety.

As the temperature of the cable rises, so does the linear resistance, resulting in a higher voltage drop and decreased system output.

When cable derating is not required?

Cable derating is not required in the following situations:

-

Single Cable Installation: When a single cable is installed in open air or a well-ventilated area with no other heat sources nearby, it can dissipate heat effectively without needing a derating factor.

-

Low Ambient Temperature: If the ambient temperature is significantly lower than the standard temperature used for ampacity calculations, the cable’s ability to carry current may already be sufficient.

-

No Cable Grouping: When cables are not bundled or grouped with others, there is minimal mutual heating, eliminating the need for derating due to heat buildup.

-

Shallow Burial with Good Ventilation: For cables buried at shallow depths with adequate thermal conductivity in the surrounding soil and minimal heat insulation effects, derating may not be needed.

-

Short Cable Runs: For short cable runs where heat does not have enough time to accumulate, derating may not be required.

-

Designed for High Temperatures: If the cable is specifically designed to operate at higher temperatures (e.g., high-temperature-rated cables), derating factors may not apply under standard conditions.

-

Compliant Installation Conditions: When installation conditions align perfectly with the cable’s rated ampacity specifications (e.g., spacing, ambient temperature, soil thermal resistivity), derating isn’t necessary.

In all cases, ensure that the installation conditions match the standards used for the cable’s ampacity rating to confirm that derating is unnecessary.

Various factors of derating cables

Various factors can necessitate the derating of cables, including:

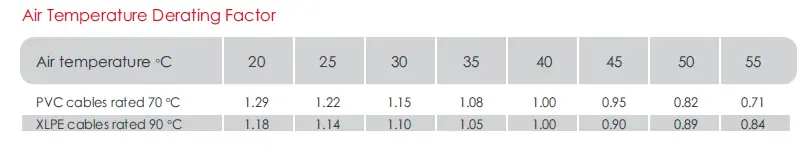

Air ambient temperature derating:

Cable temperature is one of the most important factors which affect current carrying capacity. The higher the temperature, the lower the current the cable can carry.

The ampacity of a cable should be equal to or greater than the maximum current that it’s expected to carry during its service life while not exceeding its temperature rating.

The temperature rating is determined by the heat resistance of the components used in the cable’s coating and sheath.

Cable ampacity derating is also applied for both ambient and ground temperatures.

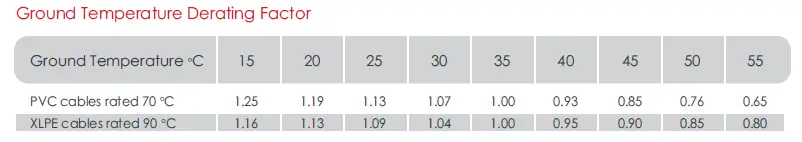

Ground temperature derating:

Just like the air temperature, the ground temperature affects electrical cables’ ampacity.

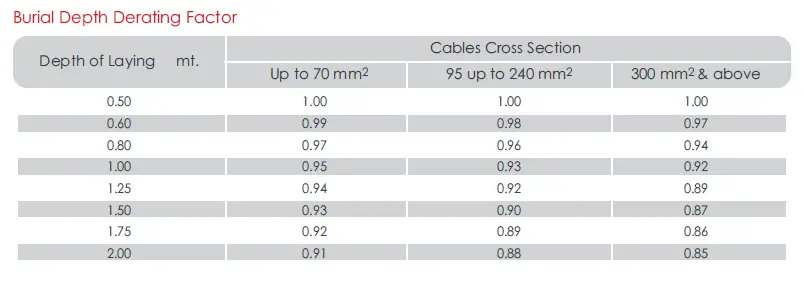

Burial depth of cable:

Buried cables depend on soil to reduce cable temperature. So the current of the cable should be derated according to soil temperature to protect the cable from overheating.

Each cable has a designed laying depth, If the laying depth is not the same as the designed value, then you should apply the Laying Depth factor.

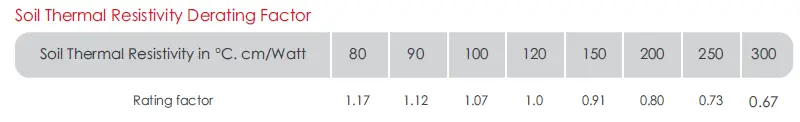

Soil thermal resistivity correction table

Soil thermal resistivity is one of the most important factors in cable laying underground. This importance is because it directly affects soil conductivity and its ability to reduce cable temperature.

Cables buried in the ground must emit heat into the environment. Soil heat conductivity varies substantially based on soil characteristics such as closeness to a water source, coastal area, dry soil, and desert sand.

The higher the level of thermal resistance, the more difficult it is to remove heat from the cable. As a result, the cable size becomes a significant consideration when applying the de-rating factor.

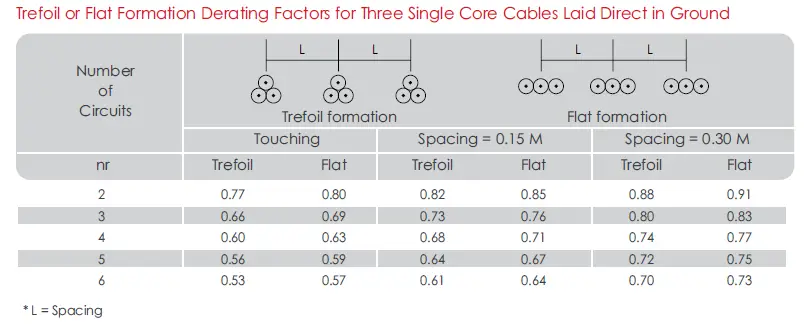

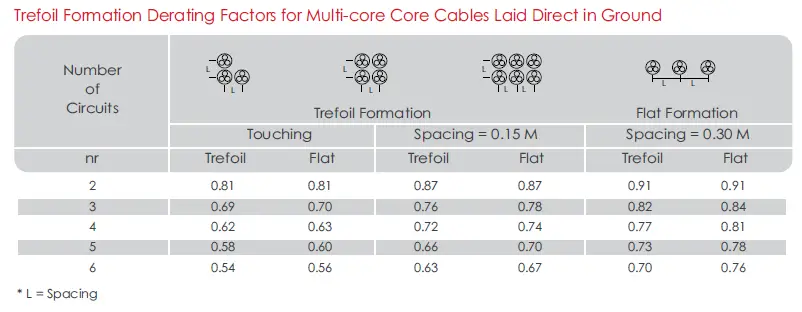

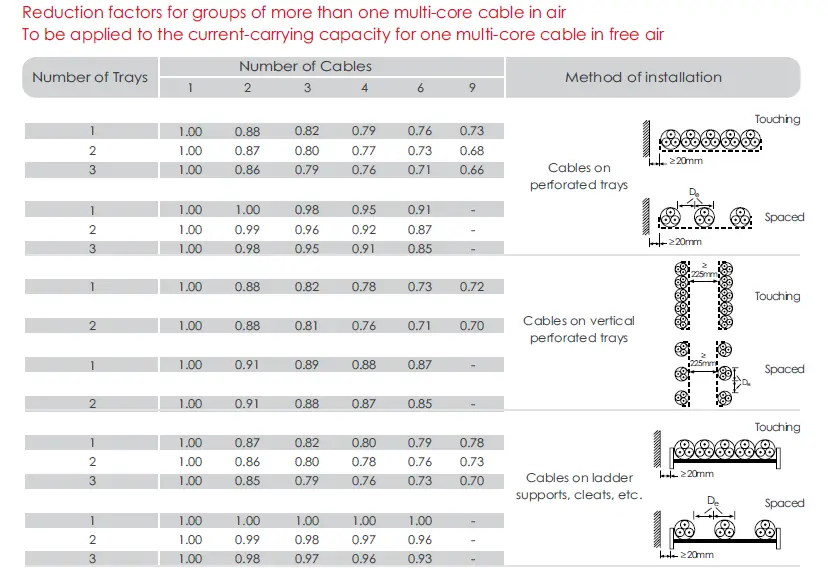

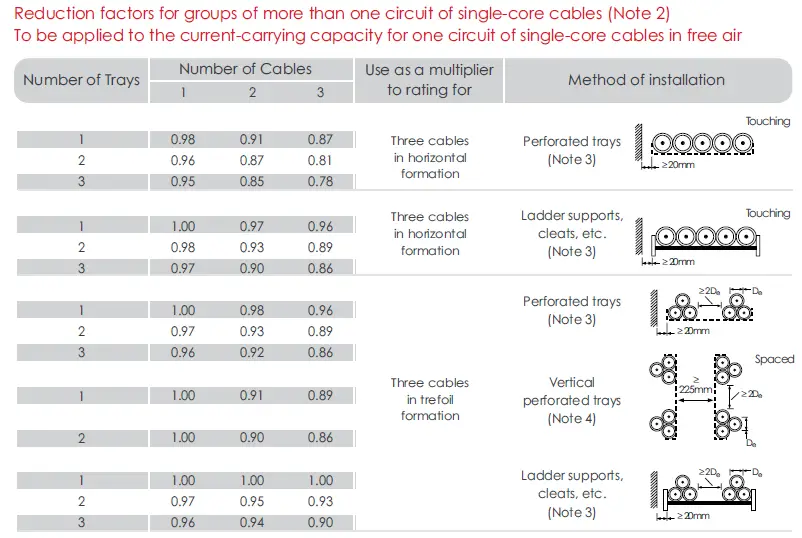

Cables formation factors

The cable manufacturers provide derating factors for a variety of options, including the number of installed cables in a layer, the number of layers, and cable spacing horizontally and vertically.

The true situation is the result of an insufficient mix of cable installation and cable manufacturer characteristics.

International standards (IEC, ERA, etc.) have been developed to address this issue. Similarly, rules established a deduction factor for a group of cables in a cable ladder or inside a duct bank.

It is common for cables to encounter a variety of climatic conditions as they travel. The environment with the largest rated current derating factor should be chosen and applied to the whole cable path.

This criterion is generally eased if the length of the cable route is less than 0.35 m. In the below tables, the formation of the cables affects their current capacity.

How to calculate cable derating?

Say we have 95 mm2 cable. If we lay this cable underground in soil with a temperature of 40°C and thermal resistivity of 150°C. cm/watt and the laying depth is 1.5 m.

Then the cable ampacity should be multiplied by three correction factors.

- laying depth (K1)

- soil temperature (K2)

- soil resistivity (K3)

Derating factor formula = Cable current * K1*K2*K3*K4…*Kn, While K’s are the derating factors of the cable.

Total derating factors = K1*K2*K3 = 0.95*0.9*0.91 =0.77, Then multiply this value by the cable current. The resulting current should be the new current carrying capacity for the cable.

After applying all derating factors we check if the cable is still suitable for the load current. If the cable’s new ampacity is less than the load current, then we choose a larger size cable.

Then we apply the same derating factor again to the new cable current and check if it is suitable for the load current.

When Should I apply cable temperature derating?

According to the National Electrical Code (NEC), temperature derating must be applied in two circumstances: when the ambient temperature reaches 30 degrees Celsius and when there are more than three cables bundled together in one conduit. This will enhance the cable’s operation and safety.

Wires can be affected by the environment to an extent by the ampacity of their conductors.

Based on an ambient temperature of 86°F, ampacities are calculated in accordance with NEC® Table 310.15 (B) (16).

In the case that the temperature exceeds 86°F, the ampacity from the table must be corrected according to the values contained in NEC Table 310.15 (B) (2) (a).

Among the factors considered in derating tables are the amount of heat produced by the current, the ambient temperature, and the temperature of the surrounding wires.

Why does the depth of burial affect cable ampacity?

The depth at which cables are buried affects their ability to carry current (ampacity) due to temperature differences. Soil around buried cables acts as a thermal insulator, stabilizing temperatures.

Deeper burial reduces exposure to surface temperature changes, but the temperature at greater depths is usually higher than the average air temperature. This higher ambient temperature can affect the cables’ ability to release heat, increasing their operating temperature.

To ensure cables operate safely and efficiently, their ampacity must be adjusted using a derating factor. This accounts for the higher and more stable temperatures at depth, preventing the cables from overheating.

Considering burial depth is critical for accurately calculating cable ampacity and maintaining the reliability of the electrical system.

Why does cable grouping affect the correction factor?

Grouping cables together can affect their performance because they generate heat and make it harder for each cable to cool down. This increases the temperature around the cables, which can lead to higher conductor temperatures than they’re designed to handle.

To keep cables safe and efficient, their current-carrying capacity (ampacity) needs to be adjusted using a correction factor, also called a derating factor. This factor accounts for the extra heat caused by cable grouping.

Applying the right correction factor helps prevent overheating, protects the cables, and ensures the electrical system remains safe and reliable.

How does ambient temperature affect cable rating?

The current rating of all cables decreases when the ambient (environmental) temperature, whether air or soil, approaches the maximum conductor temperature limit. The higher the temperature the higher the cable resistance the lower the cable ampacity.

The relationship between current rating and air temperature for cables in the air is a non-linear function of the excess of cable surface temperature above ambient air temperature and cable size (outer surface area) also matters.

The rate of change in current rating with ambient air temperature varies with cable size (diameters).

Medium voltage cable de-rating factor.

Derating factors and tables of medium voltage cables are the same as the low voltage ones.

Current rates for medium voltage cables are established by the International Electro-technical Commission standard IEC 60502. The derating factor is used to calculate the cable rating.

Voltages up to 1 kV are covered in Part 1 of the IEC 60502 standard, whereas voltages from 1 kV to 30 kV are covered in Part 2. Part 1 does not include any current capacity sizing since IEC 60364 is expected to take care of it.

Component 2 Annex B provides a method for calculating current capacity at voltages covered by this component.

Do overhead power lines need a derating factor?

Derating factors are typically not applied to overhead power lines in the same way they are applied to cables in enclosed spaces or underground installations.

Overhead power lines are exposed to ambient air, and their heat dissipation is not as restricted as that of cables in confined spaces.

However, some factors can indirectly affect the ampacity or current-carrying capacity of overhead power lines, such as:

- Ambient temperature: Extreme weather conditions, such as high temperatures, can impact the performance of overhead power lines. While derating factors might not be explicitly applied, the thermal expansion of the conductors and the increased resistance of the wires at higher temperatures can affect their overall transmission capacity.

- Wind and ice loading: Overhead power lines are subject to the mechanical stresses induced by wind, ice, and other environmental factors. Although this doesn’t directly affect derating in the traditional sense, it can impact the mechanical design and safety considerations of the lines.

While derating factors might not be applied directly to overhead power lines, these lines are designed with built-in safety factors to account for temperature variations and mechanical stresses.

Electrical engineers and utility companies consider various factors in designing and installing overhead power lines to ensure they operate within safe limits and can withstand the expected environmental conditions over their operational lifespan.

For more information about OHTL, read my other detailed article here.