Temperature kills electric devices. It has a bad effect on cables, motors, transformers, and all electrical devices. In this article, I will discuss how Temperature affects electrical equipment.

Table of Contents

How does temperature affect current and voltage?

Temperature can have significant effects on the electrical properties of materials and components, impacting current and voltage in electronic circuits. Here’s how temperature influences these electrical parameters:

- Resistance:

- For most conductors, resistance increases with temperature. This phenomenon is described by the temperature coefficient of resistance, typically denoted by the symbol α. The relationship between resistance (R), initial resistance at a reference temperature (R₀), temperature (T), and the temperature coefficient (α) is given by the formula: R=R₀×(1+α×(T−T0)

- Metals generally have positive temperature coefficients, meaning their resistance increases with temperature. In contrast, some semiconductor materials exhibit negative temperature coefficients, causing a decrease in resistance with rising temperature.

- Current:

- According to Ohm’s Law (I = V/R), the current (I) in a circuit is inversely proportional to resistance. Therefore, an increase in resistance due to temperature rise would lead to a decrease in current, assuming voltage remains constant.

- In some cases, the electronic properties of semiconductors may change with temperature, affecting carrier mobility and influencing the flow of current through a material.

- Voltage:

- Temperature can also influence the voltage in a circuit, particularly in devices where temperature-dependent voltage sources are used (e.g., thermocouples).

- Certain semiconductor devices, such as diodes, may experience changes in voltage drop with temperature variations. For example, the forward voltage drop of a silicon diode decreases with increasing temperature.

- Power Dissipation:

- The power dissipated in a circuit (P = I²R) is influenced by both current and resistance. As mentioned earlier, both of these parameters can be affected by temperature. Consequently, changes in temperature can impact the power dissipation in electronic components.

- Semiconductor Behavior:

- In semiconductor devices like transistors, temperature can affect the bandgap energy, carrier concentration, and other material properties. This, in turn, influences the behavior of the semiconductor and can have implications for the current-voltage characteristics of the device.

It’s important to note that the specific impact of temperature on current and voltage depends on the material and components used in a circuit.

Engineers take these temperature dependencies into account when designing electronic systems to ensure stable and reliable operation across a range of operating conditions.

Thermal management is also a crucial consideration to prevent overheating and maintain the desired performance of electronic devices.

How does temperature affect electrical conductivity?

Temperature can significantly affect the electrical conductivity of materials, and this relationship varies depending on the type of material. Generally, there are two broad categories: conductors and semiconductors.

- Conductors (e.g., metals):

- Increasing temperature: In metallic conductors, as the temperature increases, the electrical conductivity typically decreases. This is because higher temperatures cause more thermal vibrations of atoms in the lattice structure, which can impede the flow of electrons. As a result, the mobility of charge carriers (electrons) decreases, leading to a rise in electrical resistance.

- Superconductors: However, there is an interesting exception. Certain materials, called superconductors, exhibit zero electrical resistance at very low temperatures. These materials undergo a transition to a superconducting state, allowing the unimpeded flow of electrical current.

- Semiconductors:

- Increasing temperature: In semiconductors, the relationship is a bit more complex. Intrinsic semiconductors (pure semiconductors with no impurities) tend to have an increase in conductivity with rising temperature. This is because more electrons gain enough energy to move from the valence band to the conduction band, creating additional charge carriers.

- Doped semiconductors: For doped semiconductors (semiconductors with added impurities), the relationship can vary. In n-type semiconductors (where electrons are the majority charge carriers), conductivity may increase with temperature due to more electrons being excited to the conduction band. In p-type semiconductors (where holes are the majority carriers), conductivity may decrease as more thermal energy creates additional holes in the valence band.

In summary, the effect of temperature on electrical conductivity depends on the material. For conductors like metals, conductivity generally decreases with increasing temperature, while for semiconductors, it can increase or decrease depending on the specific characteristics of the material and its doping.

I’ve written a detailed article about Cables Derating Factors, I highly recommend reading it for more information.

How does temperature affect resistance?

The relationship between temperature and electrical resistance depends on the type of material. Generally, there are two categories: conductors (e.g., metals) and resistors (e.g., semiconductors). Here’s how temperature affects resistance in each case:

- Conductors (e.g., metals):

- Increasing temperature: In metallic conductors, the electrical resistance typically increases with an increase in temperature. This phenomenon is known as the positive temperature coefficient of resistance. As the temperature rises, the atoms in the metal lattice vibrate more vigorously, and this increased thermal motion impedes the flow of electrons through the material. As a result, the resistance of the conductor increases.

- Mathematically: The relationship between resistance (R), temperature (T), and the temperature coefficient of resistance (α) in metals can be expressed by the formula: RT=R0×(1+α×(T−T0)) where: RT is the resistance at temperature T, R0 is the resistance at a reference temperature T0, αα is the temperature coefficient of resistance.

- Semiconductors and Insulators:

- Increasing temperature: For semiconductors and insulators, the relationship between temperature and resistance is more complex. In intrinsic semiconductors (pure semiconductors with no impurities), the resistance generally decreases with increasing temperature due to increased carrier generation.

- Doped semiconductors: In doped semiconductors, the relationship can vary. For example, in n-type semiconductors, where electrons are the majority carriers, resistance may decrease with temperature. In p-type semiconductors, where holes are the majority carriers, resistance may increase with temperature.

In summary, the effect of temperature on resistance depends on the type of material. In conductors like metals, resistance typically increases with temperature, while in semiconductors, the relationship can be more complex and is influenced by factors such as doping and the type of charge carriers.

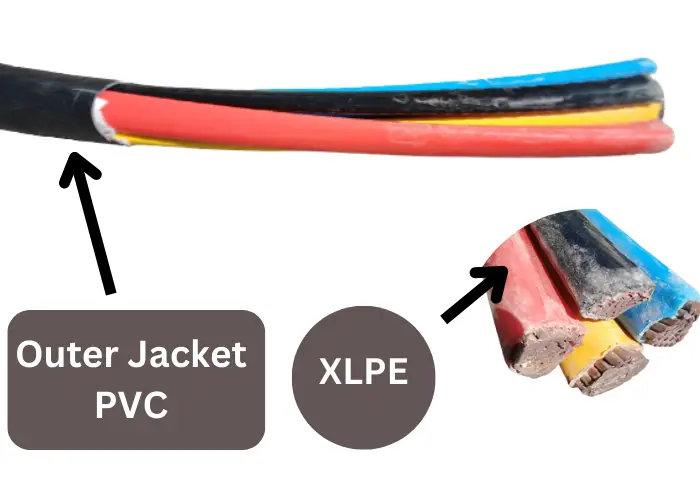

How does temperature affect wires and cables?

Temperature can have significant effects on the properties and performance of wires and cables. The impact of temperature varies depending on the type of material used in the construction of the wires and cables, as well as the specific application. Here are some general considerations:

- Conductors (Metal Wires):

- Hot Temperature:

- Resistance Increase: In metal conductors, such as copper or aluminum wires, high temperatures can lead to an increase in electrical resistance. This is due to the greater thermal motion of atoms in the conductor, which hinders the flow of electrons, resulting in a higher resistance.

- Deformation: Extremely high temperatures can cause physical changes, such as deformation or melting, in the metal conductors. This can compromise the structural integrity and electrical performance of the wires.

- Cold Temperature:

- Increased Brittleness: Extremely low temperatures can make certain materials, including some insulating materials, more brittle. This increased brittleness can make the insulation more susceptible to cracking or damage, exposing the conductive core.

- Hot Temperature:

- Insulation and Jacketing Materials:

- Hot Temperature:

- Softening or Melting: High temperatures can cause insulation and jacketing materials to soften or melt. This is especially critical in applications where fire resistance is important, as overheating can compromise the integrity of the insulation and contribute to a fire hazard.

- Cold Temperature:

- Increased Brittleness: As mentioned earlier, very low temperatures can make insulating materials more brittle, leading to a higher risk of cracking or damage.

- Hot Temperature:

- Thermal Expansion:

- Hot Temperature:

- Expansion: Different materials expand and contract at different rates with temperature changes. In cables, this can lead to thermal expansion or contraction, potentially affecting the overall dimensions and mechanical properties of the cable.

- Cold Temperature:

- Contraction: In cold temperatures, materials tend to contract. This contraction can affect the flexibility and mechanical properties of the cables, potentially leading to issues such as increased stiffness or even cracking.

- Hot Temperature:

It’s important to note that manufacturers design wires and cables with specific temperature ratings to ensure reliable performance in different environments. These temperature ratings are based on the materials used and the intended application.

Users should adhere to these specifications to prevent potential issues related to temperature extremes.

In critical applications, temperature-resistant materials and insulation with high-temperature ratings may be used to mitigate the effects of temperature variations.

Read also my other articles: Motor temperature rise causes and effects.

How does temperature affect electric motors?

If the temperature inside the motor is higher than the value of its insulation class, the insulation breaks down and the motor may burn out due to an internal short circuit.

If the temperature rise is not enough to burn out the motor, then the rise in temperature affects the motor’s lifespan. Therefore, while operating, ensure not to exceed the allowable winding temperature. I have written a detailed article about motor burn, You can read it here for more information.

As the winding temperature within the motor is not determined directly, you must measure the temperature outside of the motor’s body to examine for reference.

For more information about motor temperature rise, read my article here.

Can electric motors work in low-temperature environments?

Electric motors can generally operate in low-temperature environments, but the specific performance and efficiency may be influenced by the temperature conditions. Here are some considerations regarding the use of electric motors in low-temperature settings:

- Temperature Ratings:

- Electric motors are typically designed to operate within a specified temperature range. It’s crucial to check the temperature ratings of the motor to ensure it can function reliably in low-temperature environments. Motors with lower temperature ratings or those specifically designed for cold climates may be available.

- Lubrication:

- The lubricants used in electric motors can be affected by low temperatures. In extremely cold conditions, some lubricants may become more viscous, leading to increased friction and potential issues with motor performance. Special low-temperature lubricants may be recommended for cold environments.

- Material Selection:

- The materials used in the construction of the motor can impact its performance in low temperatures. Certain materials may become brittle or experience changes in mechanical properties in very cold conditions. Motors designed for use in cold environments may incorporate materials that are more resilient to temperature extremes.

- Insulation Resistance:

- Cold temperatures can affect the insulation materials used in electric motors. It’s important to ensure that the insulation remains effective at low temperatures to prevent electrical issues such as reduced insulation resistance.

- Start-up Considerations:

- Electric motors may face challenges during start-up in cold temperatures, especially if the lubricants are very viscous or if there are issues related to mechanical stiffness. Some motors may require preheating or other measures to facilitate smooth start-up in extremely cold conditions.

- Heating Systems:

- In some cases, electric motors operating in low-temperature environments may be equipped with built-in heating systems to prevent issues related to the cold. These heating systems help maintain the motor within the desired operating temperature range.

- Enclosure Type:

- The enclosure type of the motor can affect its ability to handle low temperatures. Motors designed for outdoor or harsh environments often have enclosures that provide protection against moisture and temperature extremes.

It’s essential to consult the motor’s specifications and the manufacturer’s recommendations to determine its suitability for a specific low-temperature application.

If necessary, additional measures such as insulation, heating elements, or specific environmental protections can be implemented to ensure reliable motor operation in cold climates.