Table of Contents

Why Is Transformer Maintenance required?

Transformer maintenance is crucial to ensure the reliable and efficient operation of electrical systems. Transformers play a vital role in transferring electrical energy from one voltage level to another, and neglecting their maintenance can lead to reduced efficiency, equipment failure, and even catastrophic breakdowns. Here’s why transformer maintenance is required:

1. Preventing Failures and Downtime

- Transformers operate under significant electrical and thermal stress. Over time, insulation materials degrade, connections loosen, and internal components wear out. Regular maintenance helps identify potential issues early and prevent unexpected failures that could cause power outages.

2. Prolonging Transformer Lifespan

- Routine inspections and servicing ensure that components like windings, insulation, and cooling systems remain in good condition, thus extending the life of the transformer.

3. Ensuring Operational Efficiency

- Accumulated dirt, moisture, or oil degradation can reduce a transformer’s efficiency. Maintenance tasks, such as oil testing, filter replacement, and cleaning, ensure the transformer operates at optimal performance.

4. Improving Safety

- Faulty transformers can pose safety risks such as fires, explosions, or electric shocks. Proper maintenance ensures all safety measures, such as insulation and grounding, are effective.

5. Compliance with Standards

- Regulatory and safety standards often require periodic testing and maintenance of transformers. Non-compliance can result in penalties or legal issues.

6. Reducing Repair Costs

- Preventive maintenance is more cost-effective than major repairs or replacing a failed transformer. Addressing minor issues early prevents them from escalating into significant problems.

7. Monitoring Load and Usage

- Maintenance activities often include checking load conditions and ensuring the transformer isn’t overloaded. This helps avoid stress on the system and ensures reliable operation.

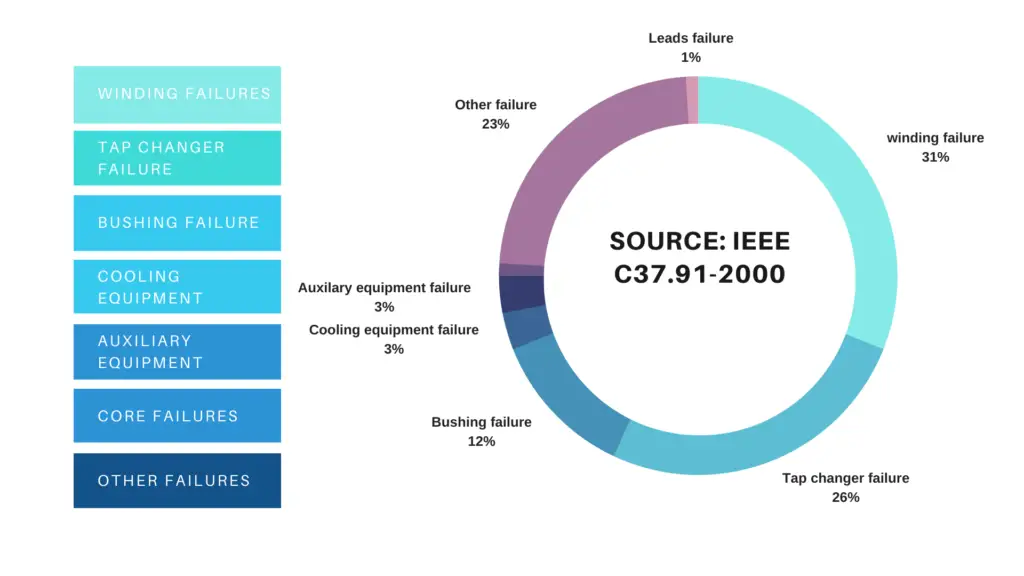

Transformers consist of many parts, Each part needs its PM. Hereunder are Statistics of failure in different parts.

Common Transformer Maintenance Tasks

The following maintenance checklist should be periodically performed (weekly is fine).

- The transformer oil level (in oil-immersed transformers) must be checked regularly to prevent dry working if the oil leakage occurs. The main job of oil used in transformers is cooling, No oil no cooling, then the excessive heat could burn the windings. Checking the oil level is done by the oil level gauge.

- Breather silica gel color. If the color changes that would mean it absorbs humidity and must be replaced. When replacing the silica gel always comply with the amount the manufacturer recommends.

- Cooling fans and oil pump check. Especially in hot areas and days. A common issue is that plastic bags come to the fans and prevent airflow. Check for damaged fan blades, And also make sure the blades are clean. Check fan rotation direction.

- Oil leakage on and around the transformer body. If any oil is found, You must check its source and repair it. Usually, oil leakage commonly happens from joints and bolts.

- Transformer temperature. Check the temperature gauge and record it. Don’t forget to check the maximum temperature red pointer.

- Check the radiator for any bird’s nests. It commonly makes nests inside the radiator.

The following checklist needs longer intervals to be performed, Annually is fine:

- Bushing cleaning and checking for cracks or broken parts. This can be done remotely without direct contact and no required power isolation. Cleaning while the transformer is energized is done using water. But must be done by an authorized and experienced team.

- Oil sampling for lab tests and analysis. The oil analysis shows us a good picture of the transformer condition, possible faults, and undetected ones.

- The pressure Release Device and Buchholz relay proper function must be checked annually.

- CT secondary connections must be checked and tightened.

- Check the control panel of the cooling fans and pumps.

Read also my article Transformer Bushings

Maintenance of transformer oil

Maintaining transformer oil is critical for ensuring the proper functioning and longevity of a transformer. Here are some essential steps for the maintenance of transformer oil:

-

Regular sampling and testing: Regularly sample the transformer oil and conduct tests to analyze its quality. Key tests include dissolved gas analysis (DGA), acidity testing, interfacial tension testing, and dielectric strength testing. These tests help in identifying any potential issues and monitoring the condition of the oil.

-

Filtration and dehydration: Implement regular filtration and dehydration processes to remove moisture, solid particles, and other contaminants from the transformer oil. This helps in maintaining the dielectric strength and overall quality of the oil.

-

Temperature control: Ensure that the transformer operates within its specified temperature range. Excessive heat can degrade the quality of the oil and reduce its effectiveness, while very low temperatures can lead to moisture condensation. Maintaining the appropriate temperature range is essential for the longevity of the transformer oil.

-

Preventive maintenance: Regularly inspect the transformer for any signs of leaks, corrosion, or other issues that may affect the oil. Implement a preventive maintenance schedule to address any potential problems before they escalate.

-

Reclamation and regeneration: Consider reclamation or regeneration of the transformer oil to extend its lifespan. Reclamation involves removing impurities and restoring the oil to its original condition, while regeneration involves restoring the chemical properties of the oil through various processes.

-

Use of suitable additives: Utilize appropriate additives to enhance the performance and longevity of the transformer oil. Additives such as antioxidants, inhibitors, and stabilizers can help in improving the oil’s resistance to oxidation and degradation.

-

Storage and handling: Store and handle the transformer oil properly to prevent contamination and degradation. Ensure that the storage containers are clean, dry, and sealed tightly to avoid the entry of moisture and foreign particles.

-

Compliance with standards and guidelines: Follow the guidelines and standards provided by relevant authorities and organizations for the maintenance and handling of transformer oil. Adhering to these standards ensures the safety and optimal performance of the transformer.

Regular and thorough maintenance of transformer oil is essential for preventing potential issues and ensuring the reliable operation of the transformer over its operational lifespan. Regular monitoring, timely testing, and adherence to best practices can significantly contribute to the longevity and efficiency of the transformer oil.

Transformer maintenance checklist

Certainly! Below is an example of a simple maintenance checklist table for a transformer:

| Maintenance Checklist for Transformer |

|---|

| Item to Check | Maintenance Task |

|---|---|

| Visual Inspection | Check for physical damage, leaks, and overheating signs. |

| Electrical Testing | Perform insulation resistance, turns ratio, power factor, and winding resistance tests. |

| Oil Analysis | Conduct DGA, moisture content, acidity, and dielectric strength tests. |

| Cooling System | Inspect and clean radiators, and fans, and check oil levels. |

| Mechanical Checks | Verify connection tightness, inspect gaskets, and lubricate moving parts. |

| Conservator and Breather | Inspect and replace silica gel if necessary. |

| Tap Changer | Inspect for proper operation and perform necessary cleaning and adjustments. |

| Safety Measures | Check safety devices, alarms, and grounding systems. |

| Documentation | Maintain detailed records of all maintenance activities. |

| Compliance | Ensure maintenance complies with relevant standards and regulations. |

Dry type transformer maintenance checklist

For dry-type transformers, regular maintenance is essential to ensure optimal performance and longevity. Here’s a maintenance checklist tailored for dry-type transformers:

| Dry-Type Transformer Maintenance Checklist |

|---|

| Item to Check | Maintenance Task |

|---|---|

| Visual Inspection | Check for any physical damage, corrosion, or contamination on the enclosure and components. |

| Cooling System | Verify the proper functioning of fans, vents, or ducts. Clean or replace air filters if necessary. |

| Insulation | Inspect insulation for signs of deterioration, cracking, or hot spots. |

| Connections | Check and tighten all electrical connections, including terminals and bus bars. |

| Temperature | Monitor temperature levels to ensure they are within acceptable operating ranges. |

| Airflow | Ensure unrestricted airflow around the transformer to prevent overheating. |

| Environmental Conditions | Evaluate the transformer’s location for factors like humidity, dust, and corrosive gases. |

| Dielectric Testing | Perform regular insulation resistance and dielectric withstand tests. |

| Overload Capacity | Verify that the transformer’s capacity matches the load requirements. |

| Sound | Listen for any unusual or excessive noise during the operation. |

| Documentation | Maintain detailed records of all maintenance activities and test results. |

| Compliance | Ensure maintenance adheres to relevant industry standards and regulations. |

This checklist provides a comprehensive guide for the maintenance of dry-type transformers. Adjustments may be necessary depending on specific transformer models, environmental conditions, and the manufacturer’s recommendations.

Regular inspections and adherence to maintenance schedules can help prevent potential issues and extend the transformer’s lifespan.

Don’t Leave Empty-Handed!

Install my Free Android App on Google Play:

Electrical Cables Most Common Tables “Cables Tables”

And, my Electrical Calculations App “Fast Electrical Calculator”

Discover more great content by subscribing to My channel

Looking to stay ahead of the game in the world of electrical engineering? Subscribe to my YouTube channel and gain access to exclusive content you won’t find anywhere else!

The staff I recommend

(Amazon Affiliate Links to products I believe are high quality):

- Economy 120 Volt/60Hz AC Power Source – Step-Down Voltage & Frequency Converters 1800W

- UNI-T Digital Multimeter Tester UT139C

- 50-Amp Extension Cord for RV “100ft”

- Voltage Stabilizer 110/220v

- Hair Dryer “best selling“

- TOSHIBA EM131A5C-BS Countertop Microwave Ovens

Disclaimer: This contains affiliate links to Amazon products. I may earn a commission for purchases made through these links.